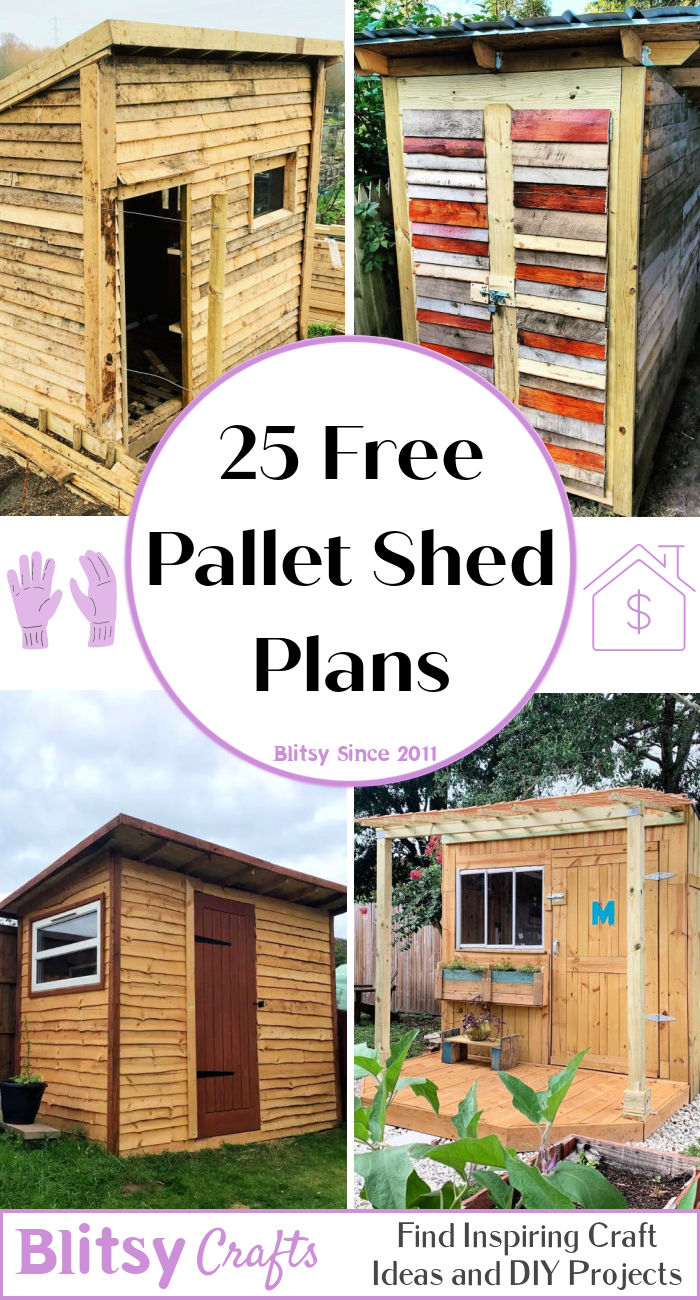

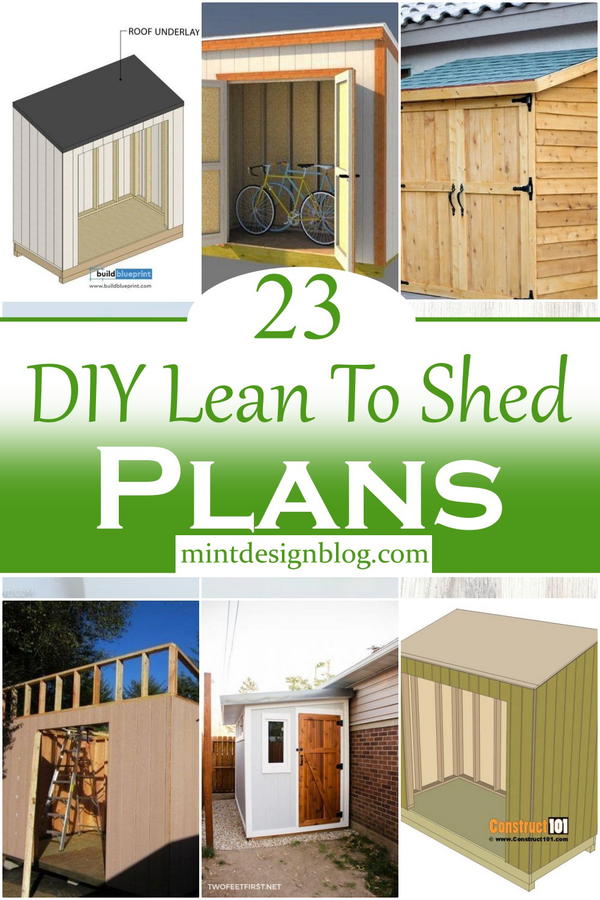

Building Your Dream Shed: A Beginner's Guide

Constructing a shed might seem daunting, but with careful planning and these beginner-friendly tips, you can build a sturdy and beautiful structure you'll be proud of. This guide breaks down the process into manageable steps, empowering you to tackle this rewarding DIY project.

Planning Your Perfect Shed

Before you even touch a tool, meticulous planning forms the foundation of a successful shed build. Start by determining the shed's purpose. Will it store gardening equipment, tools, or perhaps serve as a small workshop? This dictates the size and features you'll need. Consider the location carefully. Choose a level, well-drained spot with easy access. Check local building codes and regulations â€" you might need permits depending on your shed's size and location. Finally, sketch a detailed plan, including dimensions, door placement, window placement, and any additional features you desire. This plan serves as your roadmap throughout the construction process. Don't underestimate the value of a clear plan; it saves time and avoids costly mistakes.

Choosing the Right Materials

Selecting high-quality materials significantly impacts your shed's longevity and durability. Opt for pressure-treated lumber for the foundation and framing to withstand the elements. Consider using composite materials for siding, as they require less maintenance. For the roof, asphalt shingles offer a cost-effective and long-lasting solution. Research different options and compare prices before making your purchases. Remember, investing in quality materials saves you money and frustration in the long run.

Laying the Foundation: A Solid Start

A strong foundation is critical for a stable and long-lasting shed. Begin by leveling the ground thoroughly using a spirit level and removing any debris or vegetation. For smaller sheds, a concrete slab provides an excellent, level base. Alternatively, you can create a gravel base by compacting a layer of gravel followed by a layer of landscape fabric to prevent weed growth. Ensure the base is large enough to accommodate your shed's dimensions, leaving some extra space for error. Remember to always follow manufacturer's instructions for your chosen base type. A properly constructed foundation ensures your shed stands the test of time.

Framing and Construction: Bringing Your Vision to Life

Framing your shed involves building the skeleton that supports the walls and roof. Cut and assemble the lumber according to your plan, paying close attention to squareness and accuracy. Use appropriate fasteners, like galvanized nails or screws, ensuring every joint is secure. Construct the walls in sections before raising them, ensuring they're plumb and properly aligned. Regularly check your measurements and alignment using a spirit level and a measuring tape to prevent issues later on. Building the frame meticulously forms the crucial backbone of your shed.

Adding the Roof and Siding

Once the walls are up, install the roof trusses or rafters, ensuring they are properly spaced and aligned. Add your chosen roofing material according to the manufacturer’s instructions. Finally, install the siding, carefully aligning each piece for a professional finish. Pay attention to detail at this stage, as the siding protects your shed from the elements. Choose a siding that suits your aesthetic preferences and provides adequate protection. A well-constructed roof and siding protect your shed from the elements for years to come.

Finishing Touches: The Perfect Polish

After completing the main structure, add the finishing touches that make your shed truly special. Install the doors and windows, ensuring they operate smoothly. Consider adding shelves, hooks, or workbenches inside to maximize storage and functionality. Apply a sealant or paint to protect the wood from rot and moisture. A final coat of paint adds both protection and aesthetic appeal. These final touches transform your shed into a functional and visually appealing space.

Essential Tools and Safety Precautions

Safety first! Always wear appropriate safety gear, including safety glasses, work gloves, and sturdy footwear. Gather your necessary tools in advance, including a measuring tape, level, saw, hammer, drill, and appropriate fasteners. Having everything readily available streamlines your workflow. Remember to take regular breaks and prioritize safety throughout the entire building process. A safe and organized approach ensures a smooth and successful project.

Building a shed is a rewarding experience. With careful planning, attention to detail, and a commitment to safety, you can create a durable and functional space that enhances your property and serves your needs for years to come.